DRONES

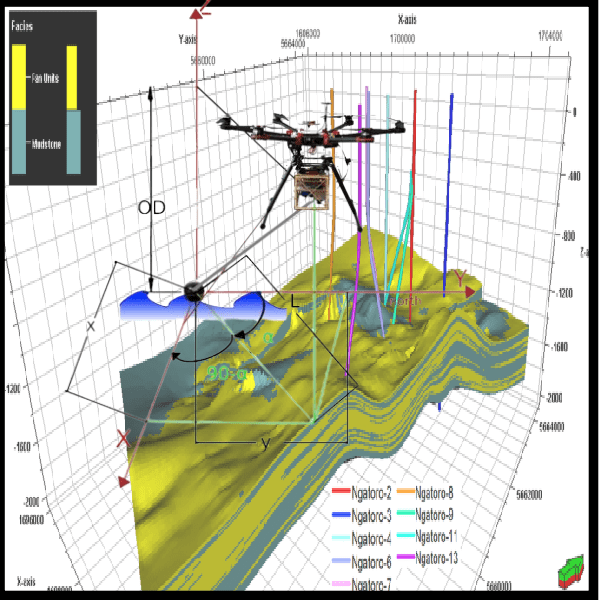

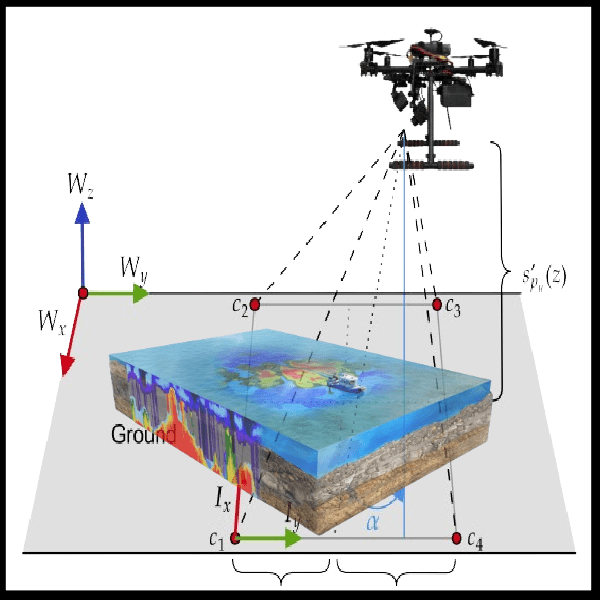

M.A offers low-altitude, aeromagnetic surveys for locating abandoned oil and gas wells and delineating buried pipelines. These techniques may also be used for mapping geology for groundwater and mineral resource exploration and development.

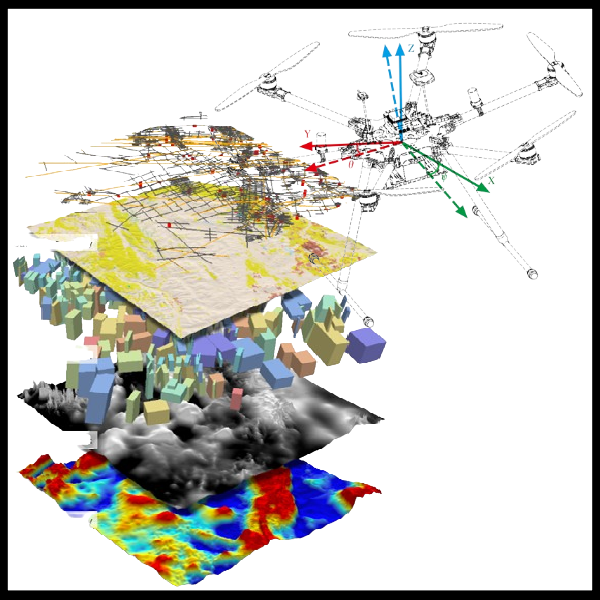

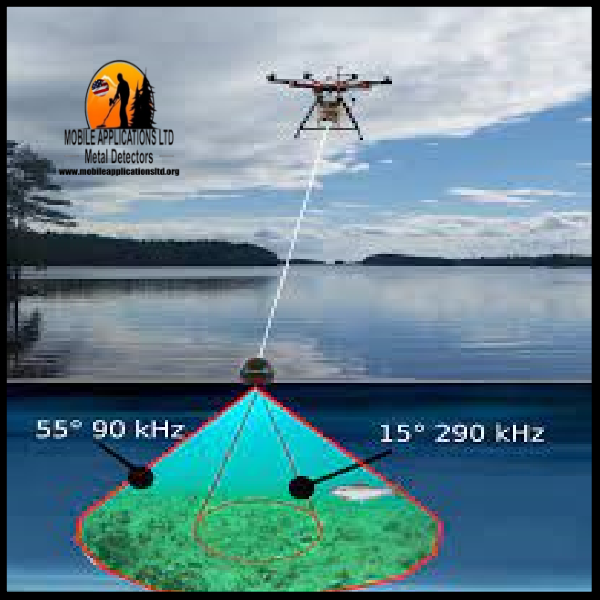

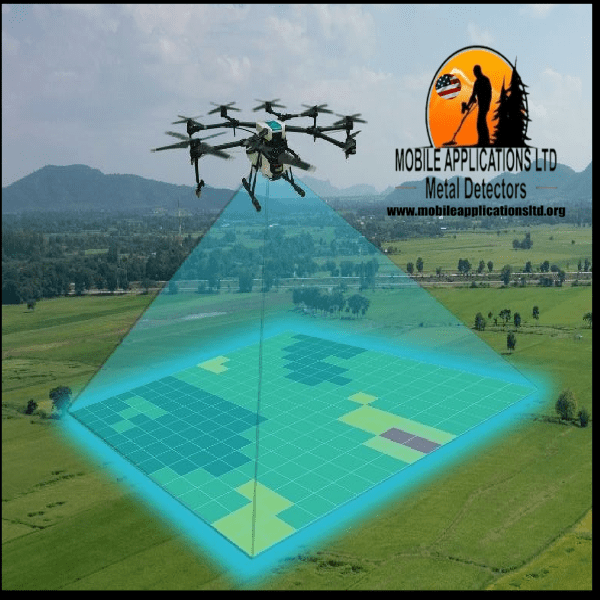

We deploy the latest innovation in magnetometer using a small unmanned aerial vehicles (UAVs) to obtain magnetic data over areas that are difficult to access or simply too large to cost-effectively survey on the ground. Color photogrammetry, thermal infrared, and LiDAR drone surveys are also offered. In addition, M.A offers data processing, visualization, and interpretation of drone magnetic and other data.

In the world of rapidly evolving technology, drone manufacturing stands out as a field that combines innovation with precision.Understanding the intricacies of drone manufacturing is vital, whether you’re a business looking to invest or a tech enthusiast interested in how these flying wonders are made.

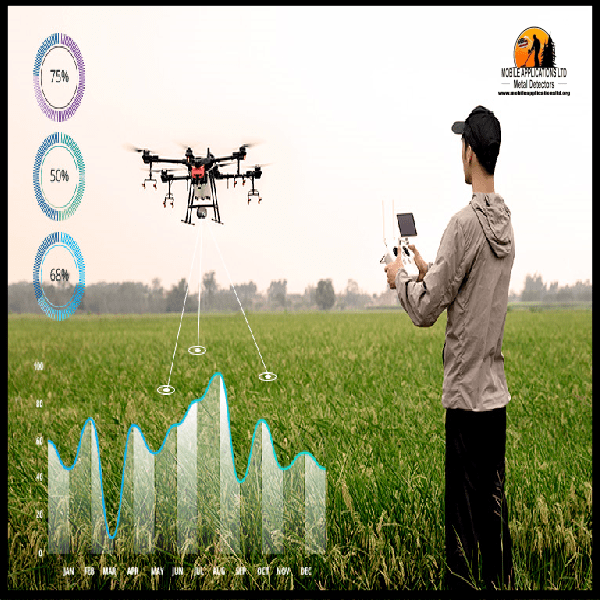

Drones have recently been used in the energy sector and are quite popular. They are actively used in the fields of mining, agriculture, construction and energy. With the new technology, drones help diagnose hotspots and find, prevent and handle potential accidents in the power industry.Drones used in the energy sector help companies save time and money. Why it is necessary to periodically examine and inspect the buildings, materials and power generation infrastructure mechanisms used in the energy sector. These tests and inspections are very expensive and involve risks. At this juncture drones take place as safe. They can both inspect very carefully and prevent challenges before they start. For the energy sector, drones are used to restore and operate parts that are difficult and dangerous to reach.

Hydroelectric plants are another facility where drones are used. In these power plants, drones are used for 3D modeling of the power plant, determining the installation area and measuring electricity prices. In addition drones play a serious role in inspection activities in areas where there are high voltage lines.

With the use of drones, detailed recording of work progress can be done on a daily basis, identifying any problems and monitoring the performance of workers. Real-time data acquisition can also improve working conditions, increasing safety on the construction site. Photos, videos, maps and models collected by drones can be used to generate reports to inform customers in real time, as well as other construction project stakeholders, increasing their satisfaction.

The initial design and prototyping stage in drone manufacturing is critical, combining detailed design with hands-on testing. Using advanced computer-aided design (CAD) software, engineers and designers build accurate 3D models, focusing on functionality, aerodynamics and aesthetics.

Rapid prototyping, especially through 3D printing, is critical to bringing these designs to life quickly. It allows component designs to be tested and refined for optimal weight, durability and performance. This phase involves thorough testing to ensure feasibility and identify design improvements, ultimately laying the groundwork for efficient production and innovative drone technology.Accuracy in drone manufacturing is of the utmost importance as it directly affects the performance, safety and reliability of aerial vehicles. The precision in the construction of each part ensures that the drone performs as intended, maintaining stability and efficiency in flight. Overall, an emphasis on precision in drone manufacturing is necessary to produce high-quality, reliable drones capable of performing complex tasks.

From initial design and prototyping to the selection of lightweight composites and metals, every step is critical to shaping the final product.

Techniques such as CNC machining and 3D printing highlight the industry’s commitment to precision and customization, while injection molding and composite manufacturing emphasize aspects of scalability and durability. Within these processes, the importance of precision cannot be overstated as it ensures the safety, reliability and efficiency of drones.

Ιn Conclusion

The journey of drone manufacturing is a complex interplay of design innovation, material selection, precision engineering and technological advancements.Mobile applications LTD can therefore provide you with the excellent construction of the drone you are interested in with your own specifications, using and integrating the most innovative technologies. Ensuring high standards of quality and safety in drone operation.

Each drone is manufactured with the highest technological applications required by each customer, MA LTD designs and implements the specifications in each country where the specific technology is available. It collaborates with different technological laboratories around the world to offer customers the highest technological services. Each cooperation with manufacturing plants in different countries is done according to the implementation project.